Applicable Industries:

Building Material Shops, Manufacturing Plant, Construction WorksÂ

Showroom Location:

Egypt, Turkey, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Mexico, Morocco, Kenya, Chile, Sri Lanka, South Africa, Kazakhstan, Nigeria, Uzbekistan, Malaysia

Condition:

New

Type:

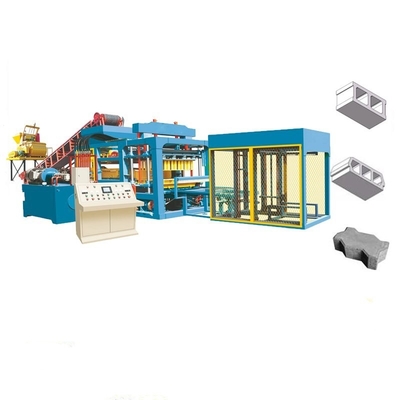

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

Brick Raw Material:

Cement, Sand, Gravels, Crushed Stone Powder, Slags, Fly Ash

Processing:

Brick Production Line

Method:

Hydraulic Pressure

Automatic:

Yes

Production Capacity (Pieces/8 Hours):

88000 Pcs/8hours

Voltage:

110-440V

Dimension(L*W*H):

8300*1860*3000mm

Warranty:

1 Year

Key Selling Points:

Automatic

Brick Size:

400*100*200 Mm, 400*120*200 Mm, 200*100*60 Mm, 300*150*100 Mm, 400*150*200 Mm, 240*115*90 Mm, 200*200*60 Mm, 150*150*100 Mm, 400*200*200 Mm, 230*220*115 Mm, 390*190*190mm,240*115*90mm,240*115*50mm

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Marketing Type:

Ordinary Product

Warranty Of Core Components:

1 Year

Core Components:

PLC, Engine, Motor, Pump, Gearbox

Weight (KG):

9700 Kg

Block Type:

Hollow Solid Paver Block Curbstone

Advantage:

Automatic Hydraulic Block Production Line

Pallet Size:

950*900MM

Model:

QT8-15

Molding Cycle:

15-20S

Machine Type:

Fully Automatic Brick Block Making Machine

Vibration Frequency:

4500r/min

Pressure:

16-22mpa

Control Mode:

PLC Full-automatical Control

After-sales Service Provided:

Video Technical Support, Online Support, Spare Parts

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!